Mold is a byproduct of the breakdown of organic matter, such as plants, wood, and even food and certain beverages. The problem posed to humans by mold is their spores, which can be released into the air and land on damp surfaces indoors, where they will continue to grow, if the conditions are right. Mold growth left unaddressed can quickly spread and result in damage to the structure of a home. More importantly, mold can compromise the respiratory health of susceptible individuals. Although testing for mold falls outside InterNACHI’s Residential Standards of Practice, home inspectors can benefit from getting trained in mold testing and offering this valuable – and sometimes life-changing – service to their clients.

Licensing or Certification Requirements for Mold Testing

Before embarking on training in order to offer mold testing services, be sure to check with your state for its requirements for certification or licensing. Some states that require home inspectors to be licensed also require mold inspectors or assessors to be licensed, such as Florida. But there are also states that don’t require home inspectors to be licensed but do require mold testers to be licensed, including Ohio.

Mold Inspections and Home Maintenance

A mold inspection starts as a home inspection, which is a non-invasive, visual examination of the home’s interior and exterior, and its various systems and components. The scope of a mold inspection requires particular knowledge of HVAC systems, roofs, the exterior, and plumbing systems. Musty odors, moisture intrusion via a roof or plumbing leak, or even evidence of suspected mold can warrant a mold inspection. Once mold gets a foothold, it cannot always be completely eradicated, so the best cure is prevention. Homeowners must be vigilant about checking for leaks both inside and outside, and making sure their home is free of conducive conditions – the main culprit being water. For instance, firewood stacked up against the side of the house can retain moisture from dew, rain and snow. Leaks should be fixed as soon as possible. And indoor humidity and moisture should be controlled by making sure appliances, such as the clothes dryer and dishwasher, are vented properly, and that the vents themselves are operating as they should. Windows are another place prone to mold growth if the frames are old and damaged, or the seals on the panes have failed. And basements and crawlspaces are notorious breeding grounds for mold, especially if they’re used only for storage, the windows are old or damaged, and/or the area experiences occasional flooding. All of these things fall under the category of home maintenance, which InterNACHI® Certified Professional Inspectors® can educate their clients about.

Testing

Mold testing involves two main methods: air sampling and surface sampling. Both types require analysis by a certified laboratory. In some cases, the local health department can test the mold samples. But it’s more common for a private lab to perform the analysis and generate the results in a report, and the cost is usually included in the price of the test kit. Along with the sampling equipment, the tools commonly used by home inspectors for a mold inspection of the home’s interior include the following:

moisture meter: This basic tool is used to detect moisture in structural components. There are invasive and non-invasive models available.

humidity gauge: This measures the humidity level inside a room or building.

thermal imaging or infrared (IR) camera: Where visual inspection is not possible, especially for suspected water intrusion that’s inside structural components, damp and wet areas can be detected non-invasively with thermal imaging. Problem areas will show up as dark gradients.

borescope: This is a camera that can visualize suspected mold growth and other problems inside plumbing pipes and structural elements through an opening in the component.

rotameter: This device measures the air flow rate, which can be helpful to determine if the home has conducive conditions for mold growth.

Air Sampling

Air sampling is conducted indoors and outdoors using spore traps or canisters. This less-common method is used for homes in areas suspected of having high concentrations of mold spores. The outdoor samples are used to create a control or baseline to determine the level of contamination, and then the control is compared to the indoor samples. When taking the outdoor sample, the home inspector should be alert to environmental conditions that can affect the results, such as wind, rain, snow, and fluctuating temperatures.

Surface Sampling

Surface sampling is the more common and easiest method for testing for indoor mold.

Here are some methods of surface sampling that can be performed:

tape sample: This is the most common method of sampling visible mold, as it allows the inspector to collect several samples in different parts of the home quickly. Sampling kits are typically sold by the laboratories that test for mold and send back the results of their analysis.

swab sample: A cellulose swab with a liquid preservative is used to collect any suspected mold for laboratory testing.

carpet sample: In rooms where there is carpeting, testing can be performed on vacuumed contents, or even a snip of the carpeting. Typically, carpets that have visible mold or have tested positive for mold should be discarded and replaced, as it’s nearly impossible to remove all traces of mold from carpet fibers, where mold will likely continue to grow.

PPE

When taking samples of mold or suspected mold, it’s important for home inspectors to be protected by wearing suitable personal protective equipment (PPE). Goggles, a respirator, gloves, a Tyvek® suit, and boot covers can be worn to protect clothing, as well as the eyes, nose and mouth.

Summary

When it comes to mold, prevention is the best way to combat it. A damp or musty smell is a likely indicator and should be investigated thoroughly. Homeowners should be encouraged to locate and repair all plumbing leaks and sources of water intrusion, which can quickly lead to mold growth. Home inspectors can get training to identify mold, as well as conducive conditions and where mold is likely to grow. Becoming certified as a mold inspector assures your clients that you understand the standards and safe practices for sampling and reporting on mold.

This article was sourced from InterNACHI® and the EPA. Special thanks to InterNACHI® member Ray Kline of All Phase Inspections for his contributions to this article.

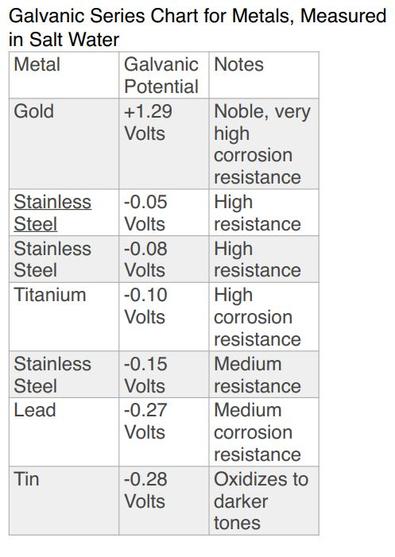

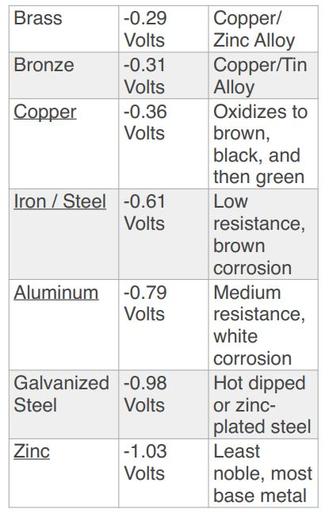

12/6/2018 Dan Paradela – Galvanic corrosion

Galvanic corrosion causing excessive rust on newly constructed homes. On a recent inspection the rear balcony was improperly installed. First of all it had a negative pitch and was holding rain water. There was also metal to metal galvanic corrosion on the sheet metal floor covering, no nylon spacers were present between the bottom of the iron rails and the sheet metal. In addition improper fasteners were used to secure the rails and again no nylon washers were present to prevent galvanic corrosion. The house was not complete, yet already extensive rust was all over the beautiful rear balcony. To prevent these issues keep these things in mind.

Galvanic corrosion is a process in which one metal corrodes preferentially when it is in direct contact with another, in the presence of an electrolyte usually rainwater or groundwater. When a metal atom is oxidized it leaves its bulk metal after losing one or more electrons and is then transferred to another site. The site where the metal atoms lose electrons is called the anode, while the site where the electrons are transferred is called the cathode. Use a galvanic series list of metals to determine which are the best metals for your project. The metals on the anodic, or less noble end will corrode faster than the metals toward the cathodic, or more noble end. It is especially important to consider the potential of galvanic corrosion when choosing metal paneling, trim, and fasteners. When choosing materials, choose metals close together on the list, as metals close together will not have as strong of an effect on each other. The farther apart the metals are on the list the stronger the corrosion on the less noble metal. You can also use nylon spacers and washers or sacrificial anodes including sacrificial metal coatings depending on the application.